ADVANCED DESKTOP PCB MANUFACTURING SYSTEM:

Single & Double Layer PCB Printing Machine:

Make: VOLTERA, Model : V ONE

More Info- Only machine which perform Drilling, Printing, Soldering and Reflow

- It creates single & double sided PCB’S.

- Build hardware faster

- Print your own circuit boards (FR1, FR4, Kaplan or Polymer sheets)

- It Loads the Gerber Files into V-One Software.

- Dispenses Solder Paste on any Circuit Board

- Quickly drill holes for vias and through holes components.

- Print Area 128mm × 116mm

- Minimum Trace Width 0.2mm

Make: VOLTERA, Model : NOVA

More Info- It Provides Pressure based dispensing.

- Enables Inspection through integrated Vision System.

- Print anything on everything.

- Enhanced Material Flexibility.

- Provides Software for everyone.

- Has Modular Platform.

- Print area 220 mm x 300 mm

- Measurement resolution +/- 2.5μm (Z-axis step resolution)

- Minimum tracewidth *100μm (0.10mm) using ACI FE3124 + 100μm nozzle

- Print height resolution +/- 10μm (0.01 mm)

- Minimum pin pitch 400μm (0.4mm)

- Minimum passive 0201* Imperial

- Inks ACI FE3124

- Substrates PET, Kapton

- Solder pastes Nordson T4 SnBiAg0.4

Double Sided PCB Mill & Engraving Machine:

Make: WEGSTR, Model : Wegstr CNC – PCB

More Info- It can perform Drilling, Milling and Engraving Etching.

- It Provides Compact design and Precision Tooling.

- Milling workspace : 140 mm (5.51 inch) (X) x 200 mm (7.87 inch) (Y) x 40 mm (1.58 inch) (Z)

- Diameter of spindle: 3.175 mm (0.125 inch)

- Connectivity: USB, USB cable length: 1.6 m (63 inch)

- Repeatability: 0.02 mm

- Spindle speed: 11 000 rpm

- It provides Cut 2D software for PCB machining

- It mills both soft and hard plastic, wood, aluminium, duralumin, PCB, balsa wood, MDF, Plexiglass, iron, copper, brass, bronze, gold, silver and more.

- It is suitable for engineers, model makers, hobbyists, goldsmiths, jewellers, watchmakers, educational institutions and many others.

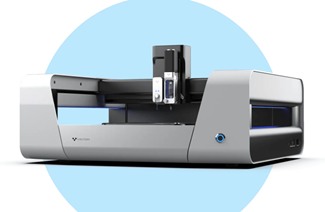

Multilayer advanced PCB Printing Machine:

Make : BOTFACTORY, US

Model: SV2 – Starter, Enhanced, Professional

More Info- Capable of printing multilayer circuits ( 2- 4 Layers)

- Dispensing paste onto pads,

- Pick-and-place components to rapidly assemble your board, using multiple vacuum tips that are automatically interchanged.

- It also uses a camera and computer vision to make adjustments and place the parts precisely.

- Inkjet print low-resistivity conductive inks and dielectric insulating inks to make Printed Circuit Boar

- Export your Gerber files from any PCB Design tool and import

- Min Trace Width: 8 mil [200 microns]

- Min Clearance: 8 mil [200 micron] – 16 mil (400 micron)

- minimum pitch size = 0.4- 0.6mm

PCB - Vision Inspection System

- PCB inspection is the act of mitigating errors or mistakes during Fabrication & Assembly Process.

- Vision systems are capable of measuring parts, verifying parts are in the correct position, and recognizing the shape of parts.

- Microscope has one HDMI port and two USB ports

- Unique all-in-one Machine design.

- Microscope has built in software to View, Capture the images & Record Videos and store it in a USB Disk

- Measuring results can be sent to Excel.

- Measuring Accuracy: within +_8 microns.

Flowcode Software

More Info- Flowcode is an advanced integrated development environment (IDE) for electronic and electromechanical system.

- Flowcode targets microcontrollers such as Arduino, PIC and Raspberry Pi.

- Non-programmer friendly

- Choice of programming methods; flowcharts, blocks, pseudo, C

- Multiple platform support and “code porting”

- Advanced Simulation

- Debugging systems – simulation debugging & code profiling

Laser Cutting Machine - C02:

- High cutting precision and positional accuracy

- Improved edge quality and surface finish

- Higher repeatability

- Advanced laser tools for material processing applications

- Drilling and engraving in addition to cutting

- Negligible work piece degradation

- Cost-effectiveness

- Minimal thermal stress zone

- Shapes High Speed belt drive plotting unit with precise micro stepping drives

- Red beam pointer

- Z- Axis (Optional)